PROJECT RE_

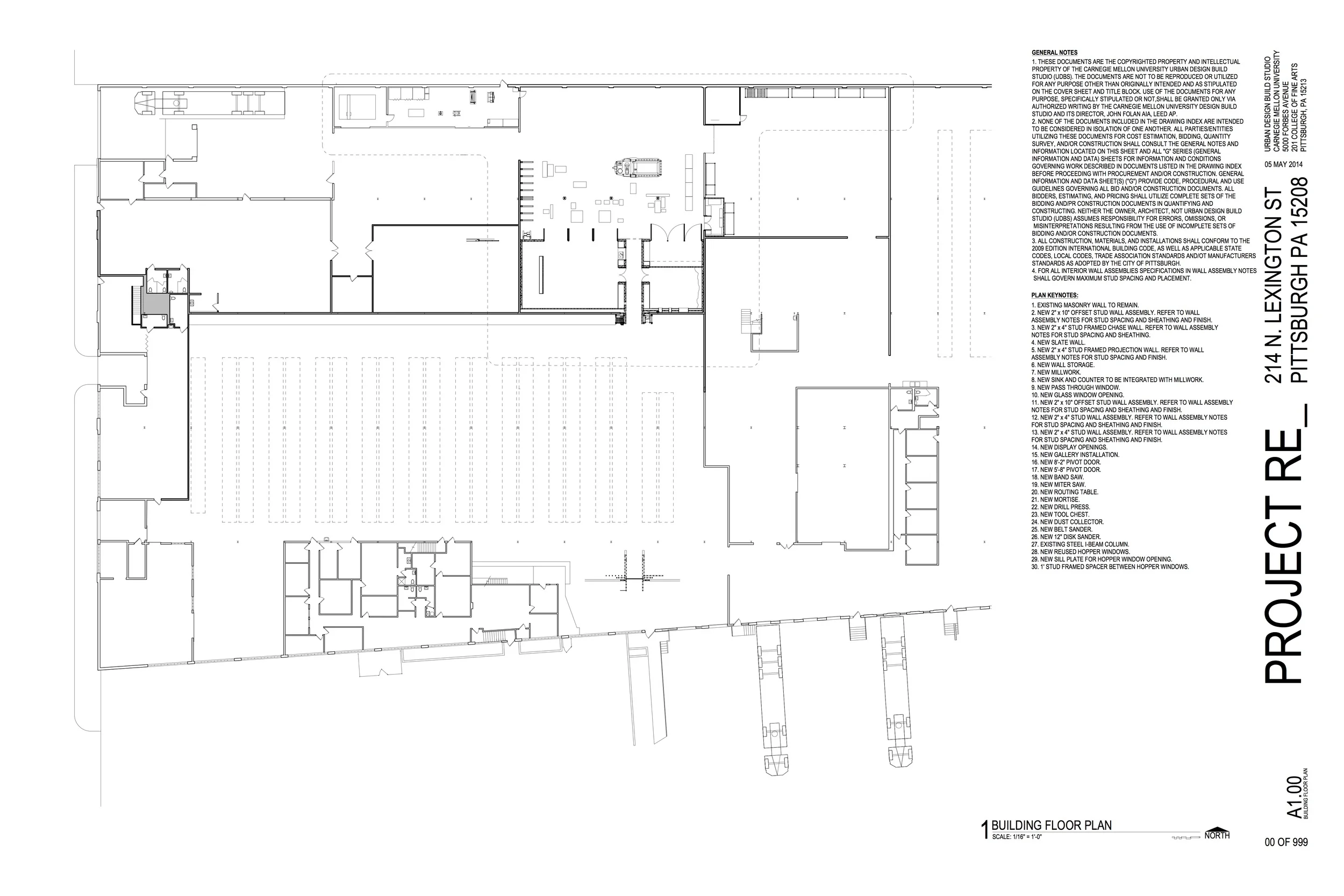

Spring 2014 | Client: Construction Junction (CJ), Trade Institute of Pittsburgh (TIP), Urban Design Build Studio (UDBS) | Funders: The Heinz Endowment, Autodesk, Ford Motor Company, Laurel Foundation, Colcom Foundation, Hillman Family Foundations | Advisor: John Folan AIA, LEED AP | Affiliation: Urban Design Build Studio (UDBS) | Location: Construction Junction, 214 N Lexington St., Pittsburgh PA

“A trade school that rebuilds lives. A building supply company that sells reused materials. An architecture program that restores communities.”

Mission

The mission of the partnership is to develop projects utilizing reused materials provided by CJ and the labor force provided by TIP. Projects will be developed with the communities it aims to serve, thereby expanding their capacity to replicate the work and ultimately restoring communities organically from within.

Diagram illustrating the unique partnership that forms Project RE_. (Courtesy of John Folan)

Trade Institute of Pittsburgh (TIP)

The TIP works with local halfway houses, jails, community centers, and anyone who wants to make a positive change to create jobs…We create more than just jobs for blighted and growing communities, TIP provides a chance for someone to rebuild their life as they rebuild the city.”

Construction Junction (CJ)

“Our mission is to support and promote conservation through the reuse of building materials. We strive to keep usable building materials out of the landfills and provide them to the community at very low cost”

Urban Design Build Studio (UDBS)

"The UDBS is a Public Interest Design entity and affiliated outreach arm of the Carnegie Mellon University School of Architecture. The mission of the UDBS is to develop regionally specific, environmentally appropriate building strategies in collaboration with residents and stakeholders in underserved urban communities."

Diagram explaining the business model of Project RE_. (Courtesy of John Folan)

Promotional video found at http://www.projectrepgh.com/

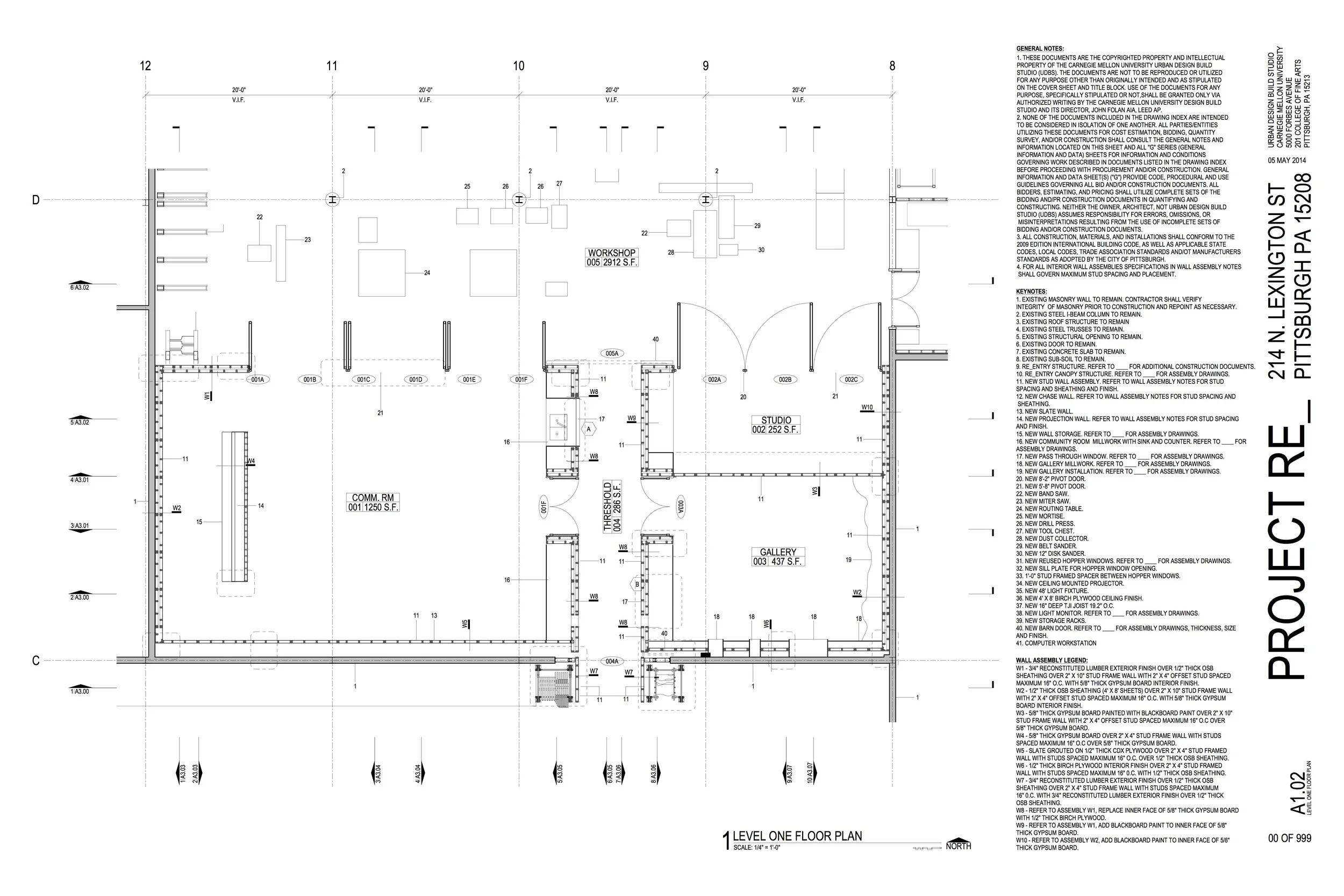

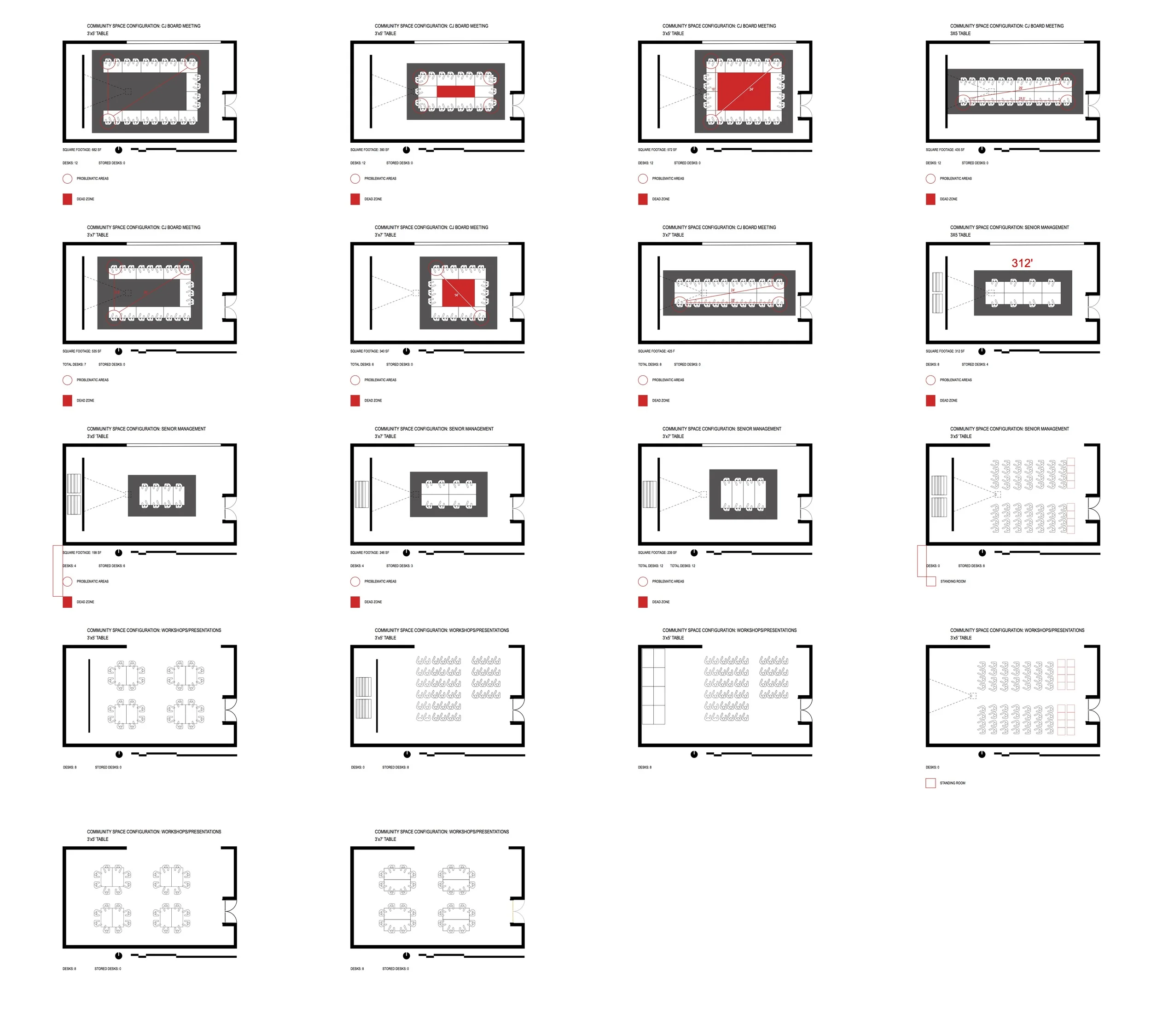

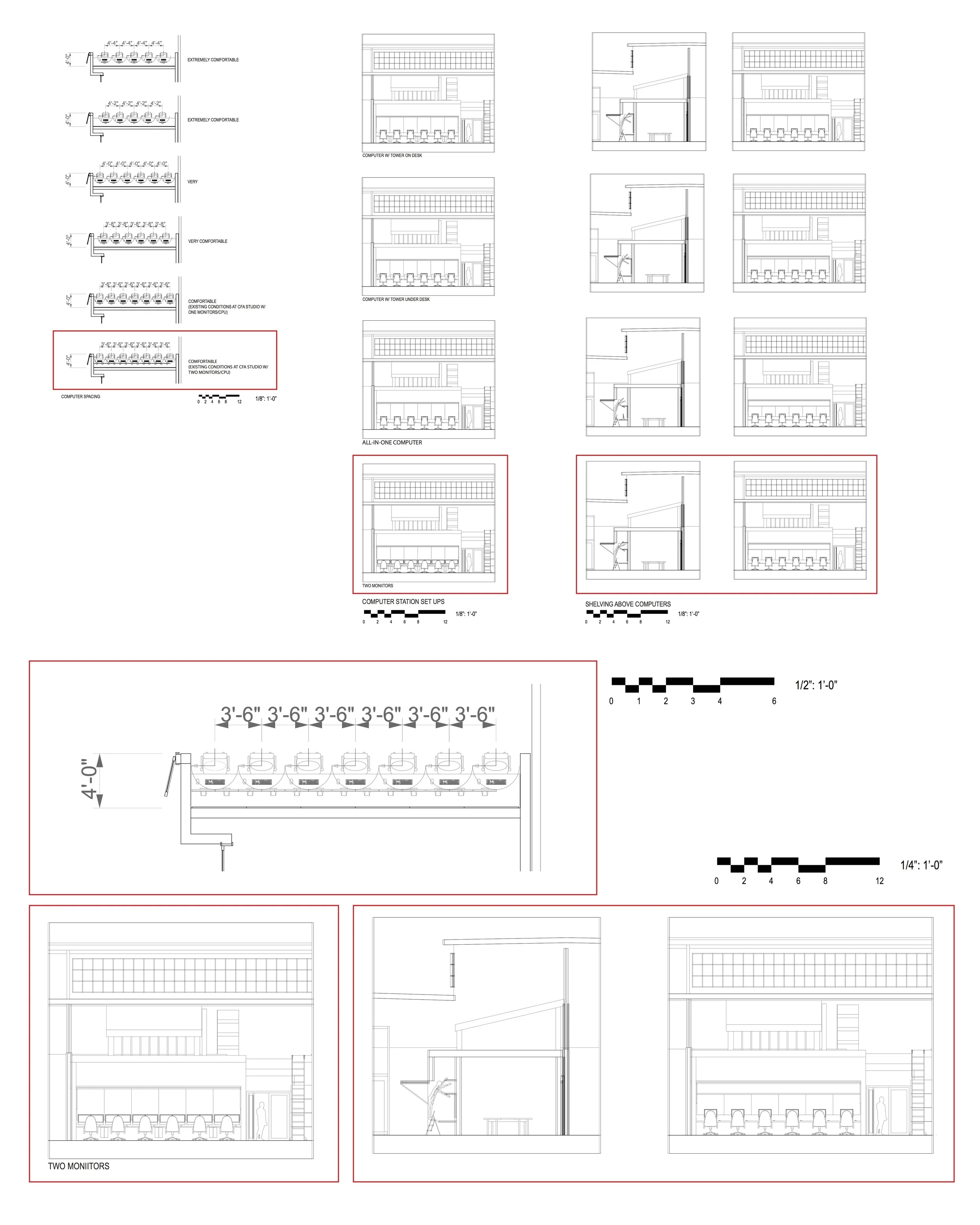

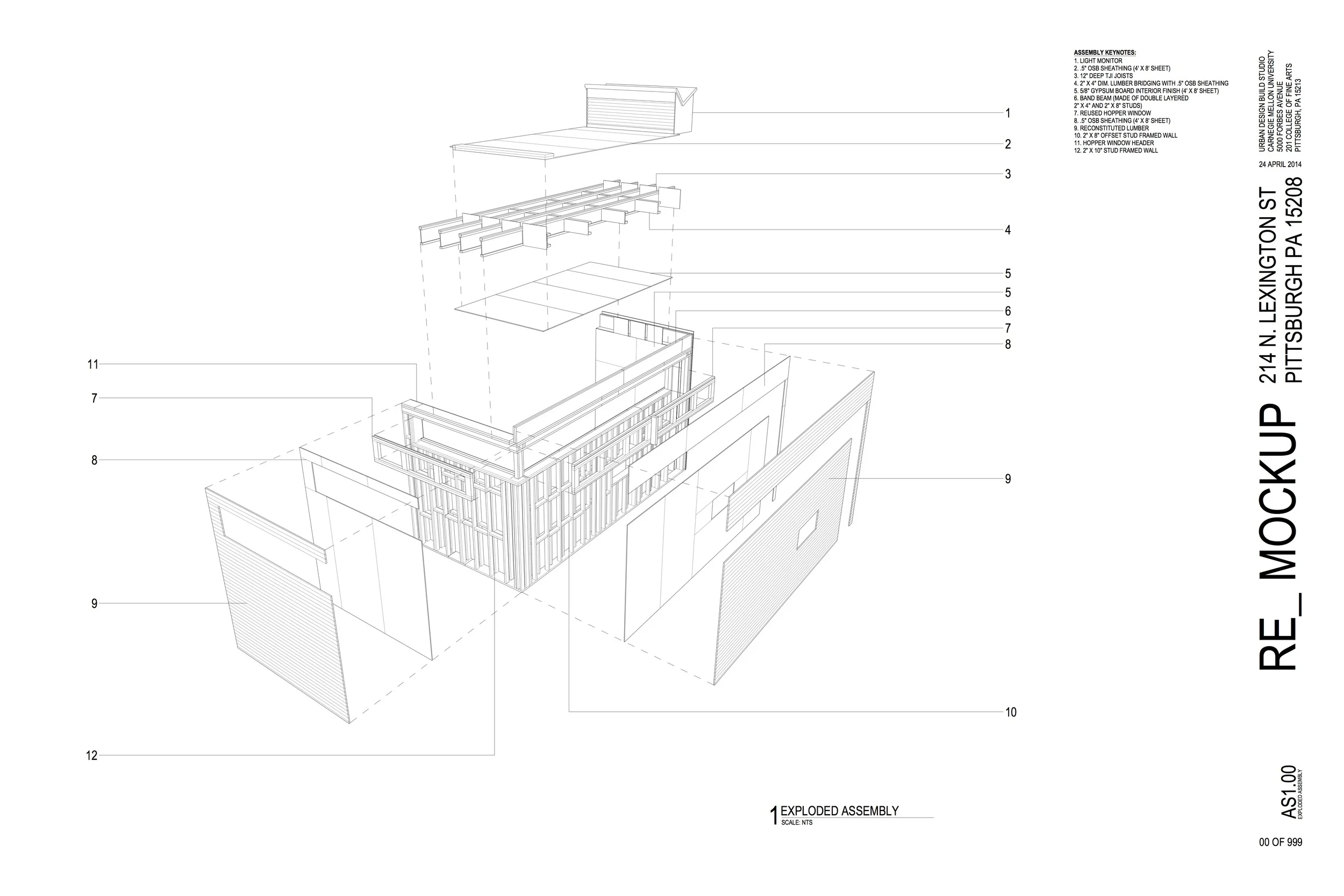

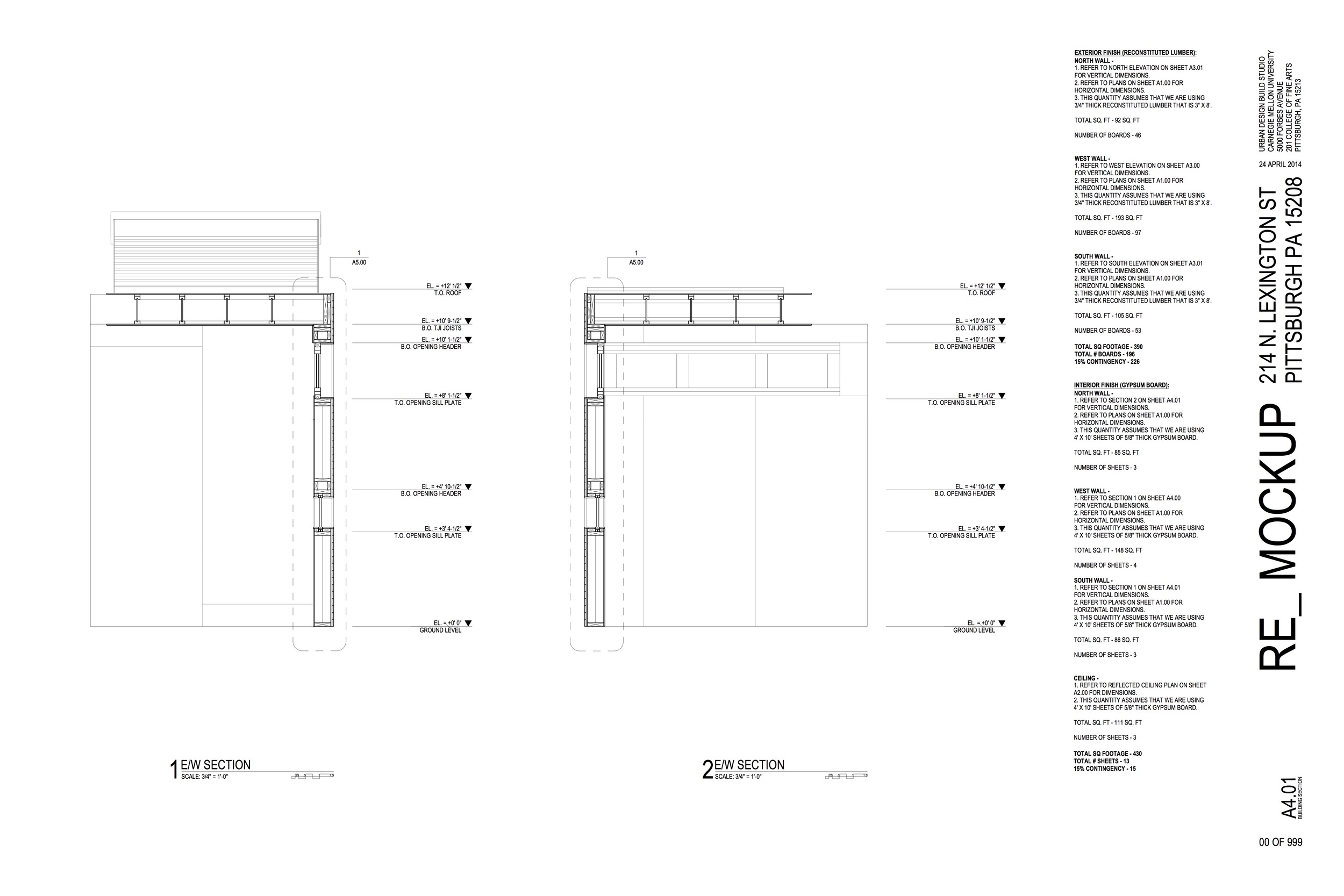

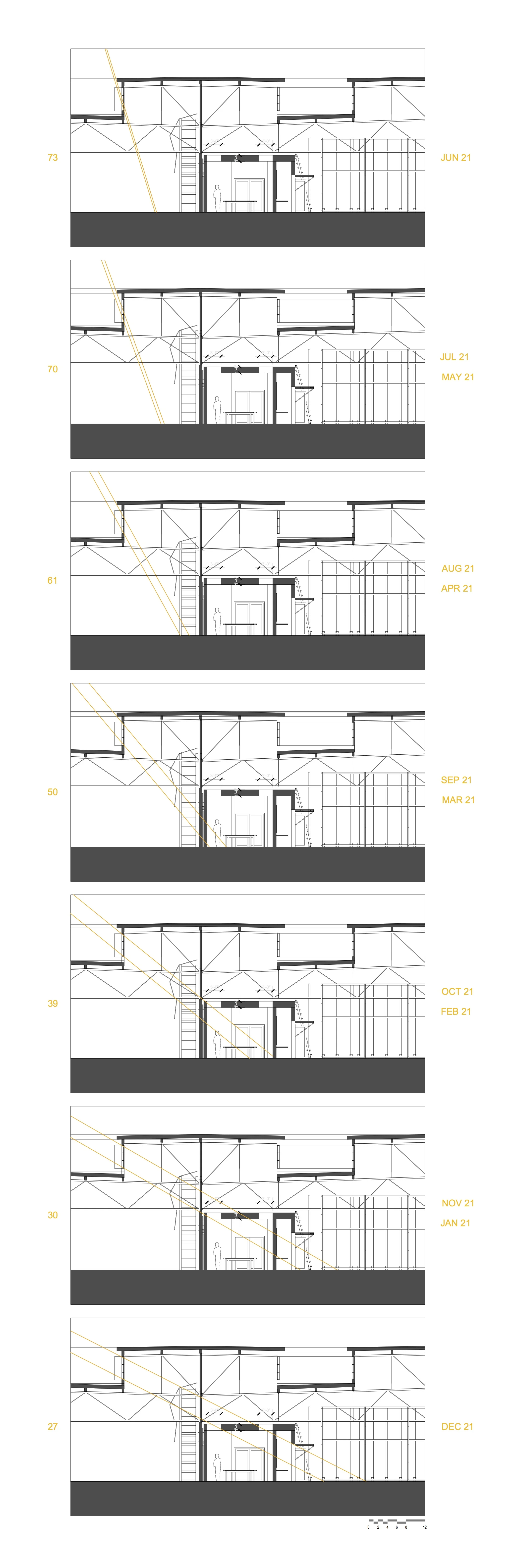

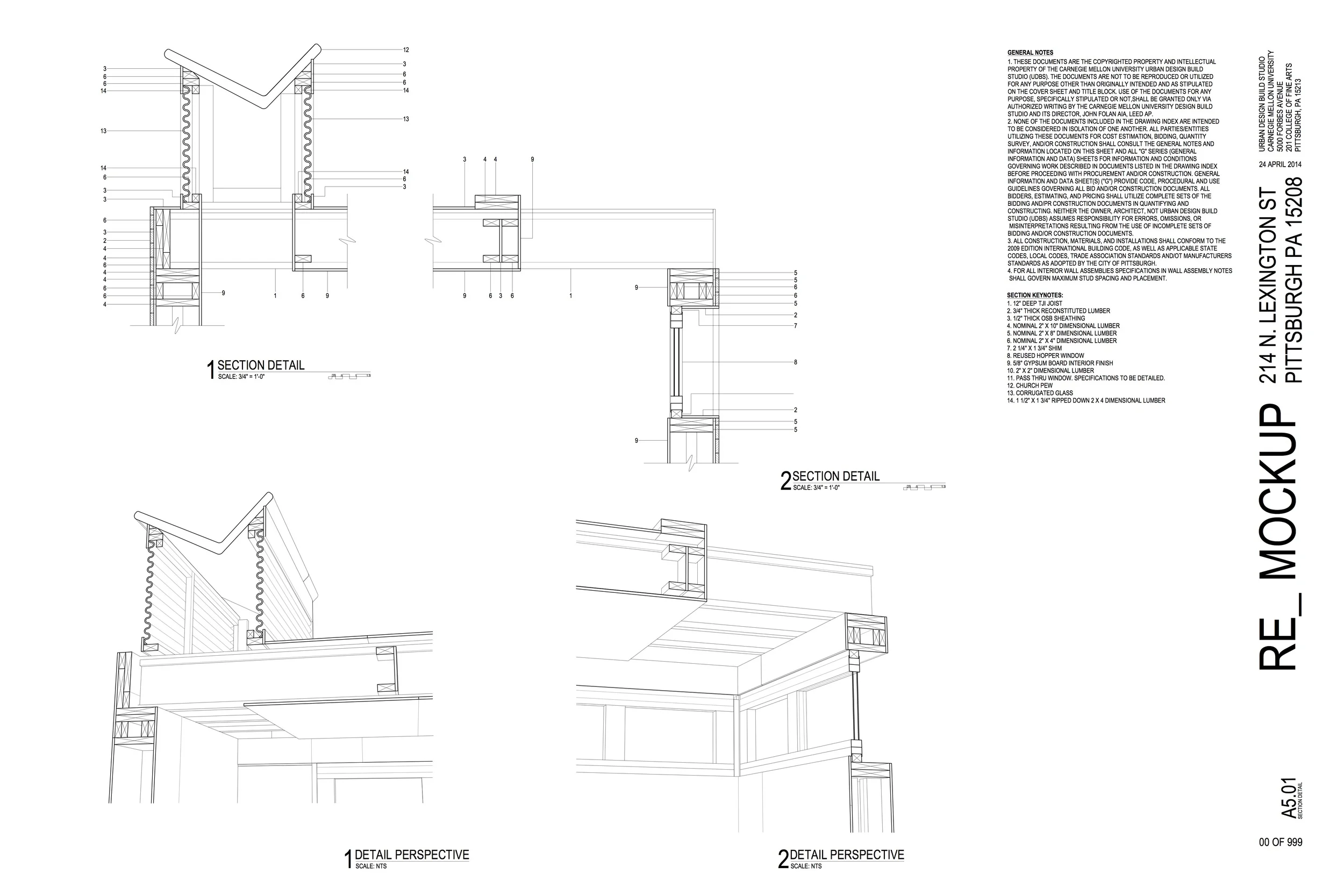

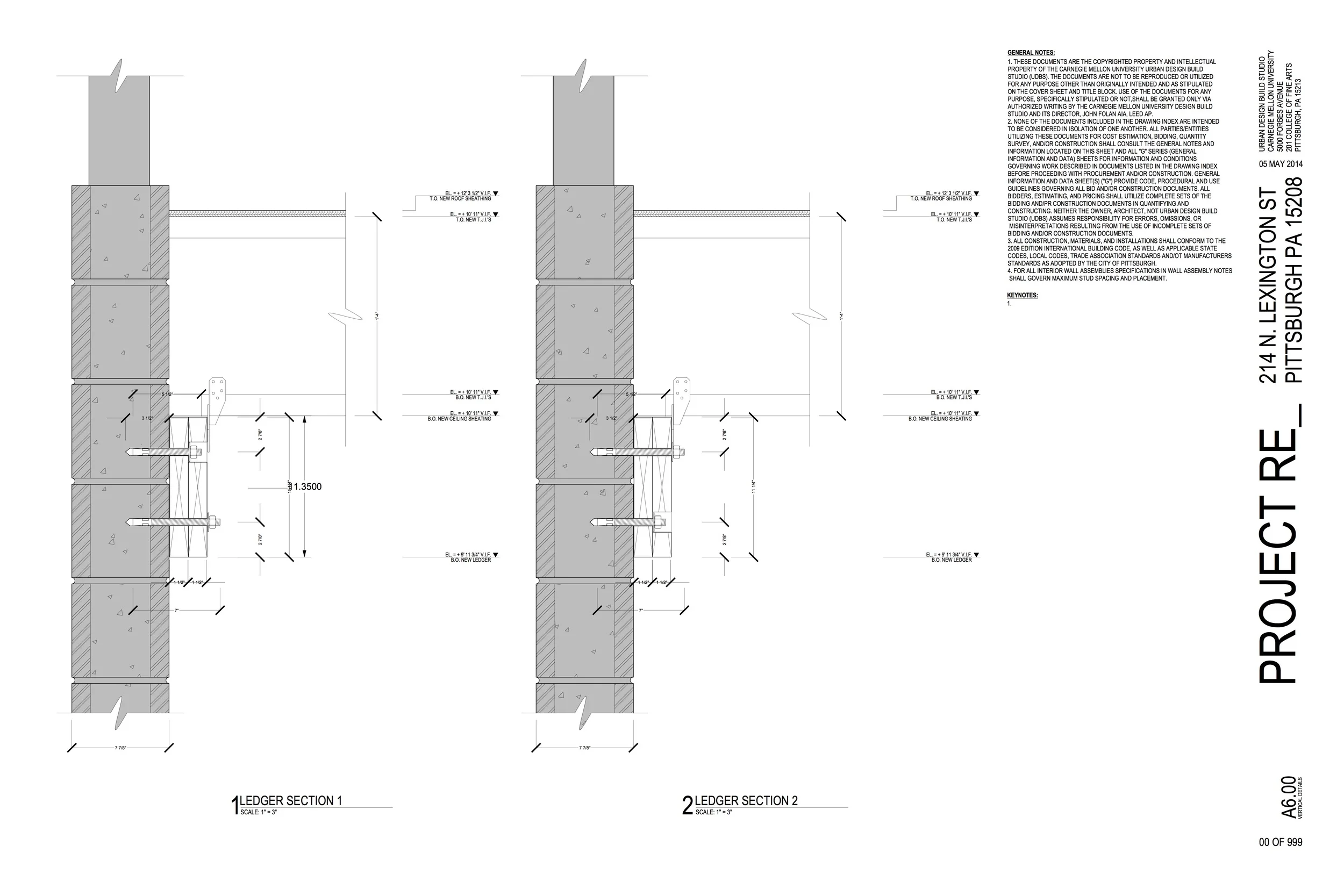

During the schematic design phase, our team developed the spaces by verifying the functionality of the proposed configurations. Besides extensively diagramming how the space will be used, we also constructed a full-scale mockup to explore materiality, lighting conditions and joint details. Further exploration of materiality and lighting conditions continued through a series of models and prototypes that were tested and evaluated in the CJ space.

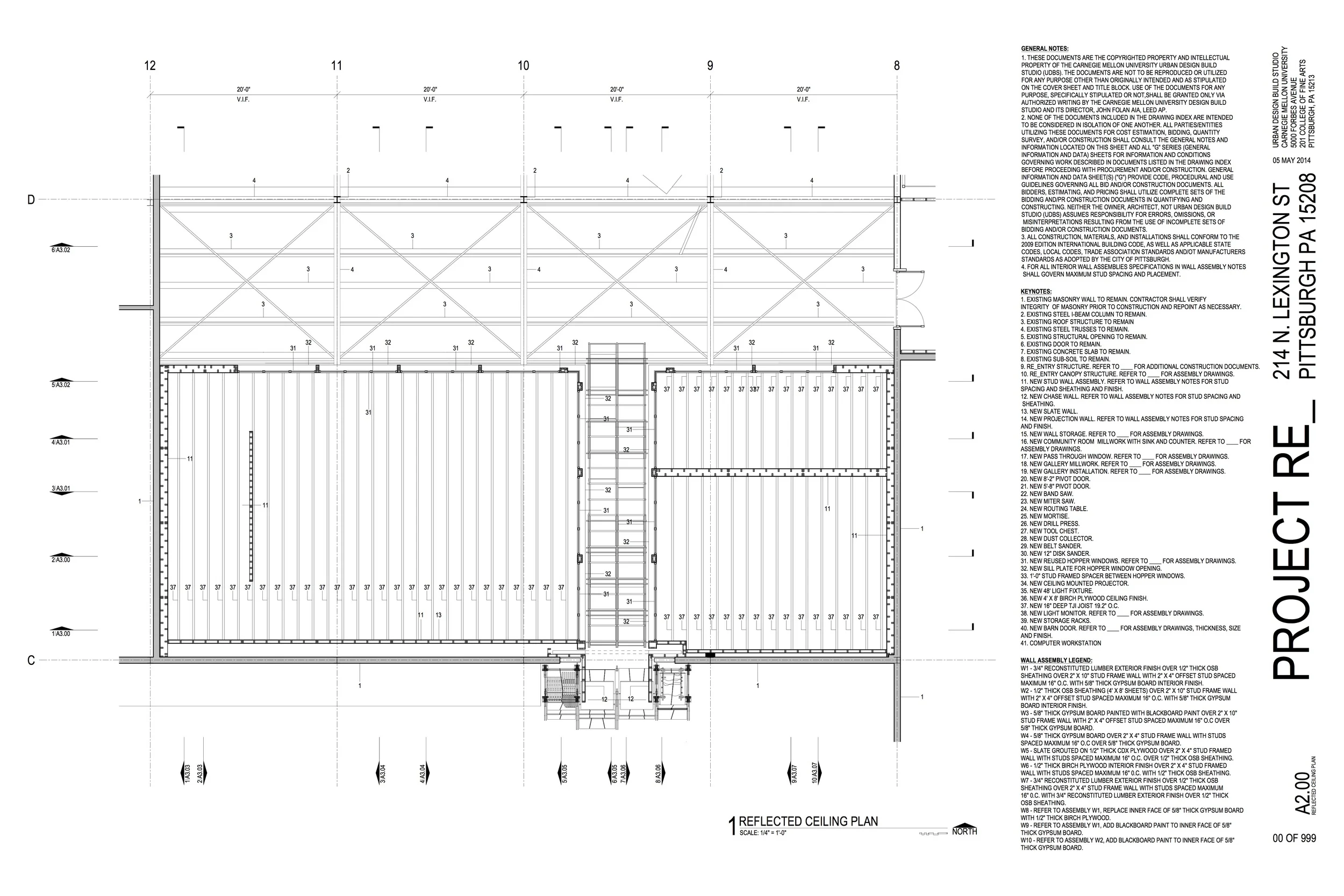

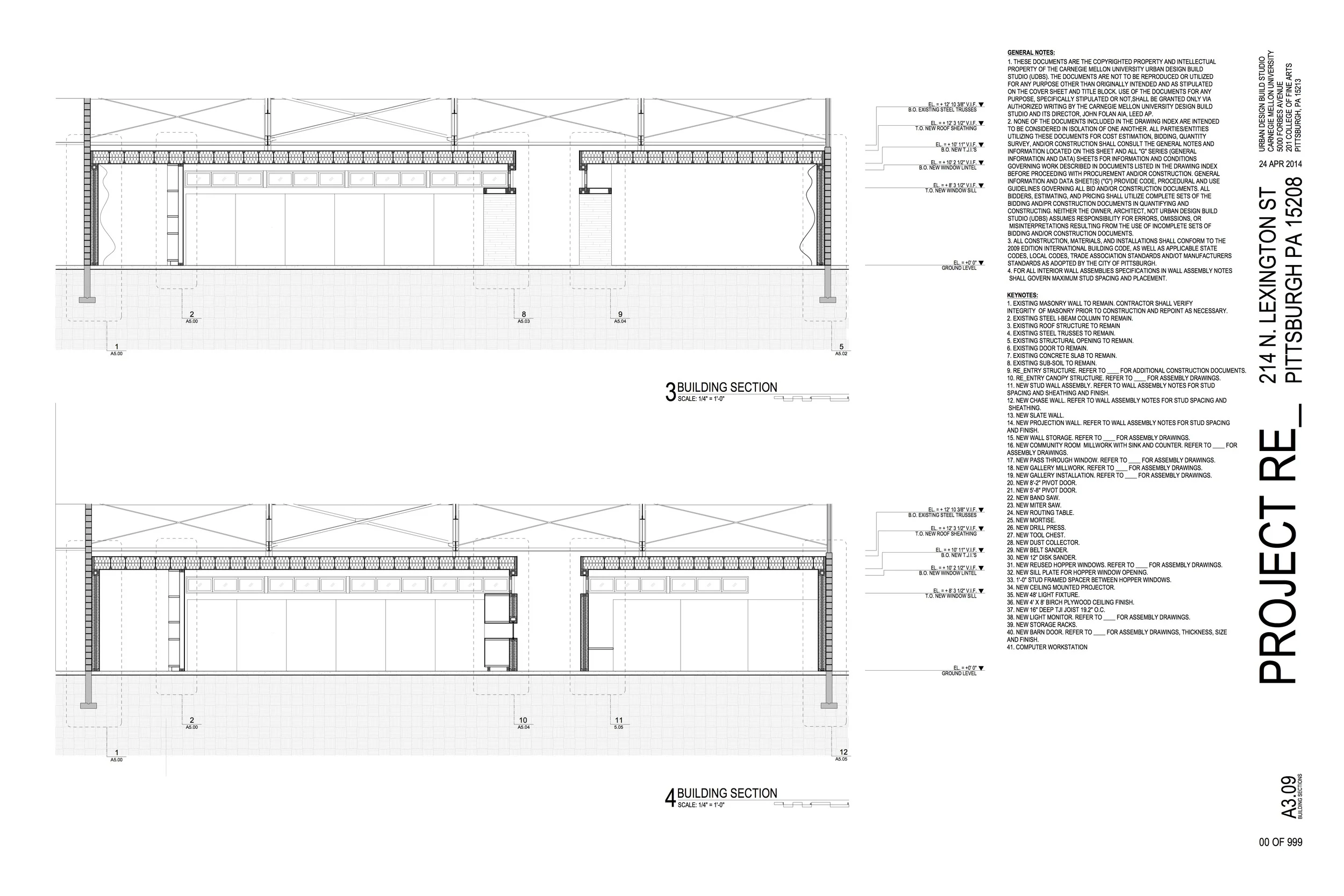

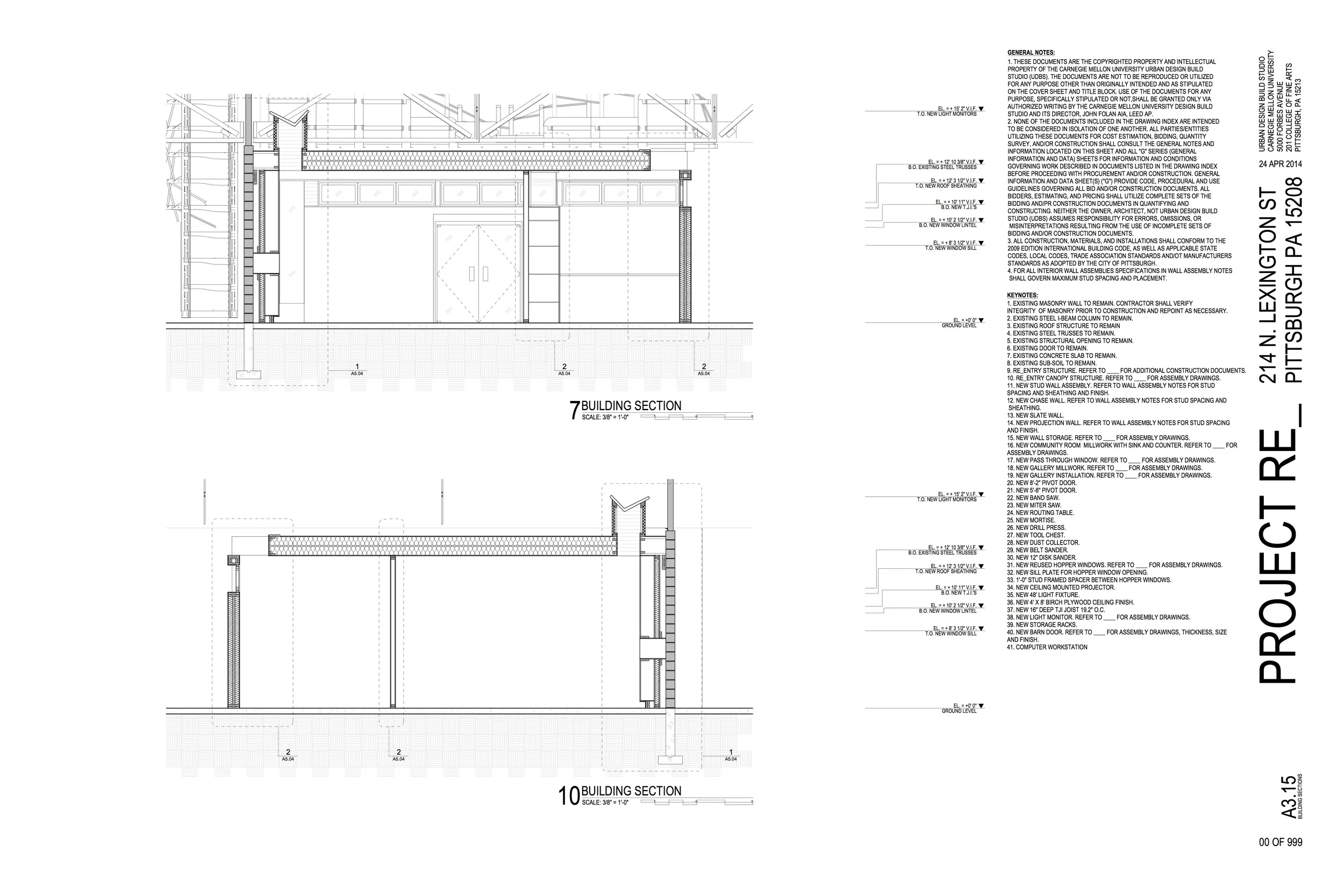

Once the client approved the schematic design, the collective focus shifted to developing framing plans and initiating construction. We did quantity take-offs for construction materials orders, and coordinated this effort while leading blitz-build sessions with TIP students.